DR3 - three-phase general purpose reactors

Dividing – for equal distribution of the load current between parallel-connected electric motors

Construction of the magnetic system of reactors of DR3 type – bar with clearance, with magnetic core, made based on UNICORE technology with butt joint, 1 non-magnetic clearance is located in the middle windings, electrotechnical steel NV30S -120, sheet thickness is 0.3 mm.

Right-hand windings, material – aluminum. At customer's request, windings can be made of copper wire or bus.

The following characteristics of the reactor are determined by the customer in agreement with the manufacturer.

Parameters of three-phase DR3 reactors.

Parameters of three-phase DR3 reactors.

| Parameter | Units | Default | Possible options |

| Reactor inductance | mH | According to Technical task | According to Technical task |

| Rated current | А | According to Technical task | According to Technical task |

| Magnetic system saturation current | А | Rated current | According to Technical task |

| Tolerance of reactor inductance | % | 10 | Any but not less than 3 |

| Winding material | Aluminum | Copper | |

| Heat-resistance class | B | F | |

| Voltage class | kV | 0,7 | 0,4 |

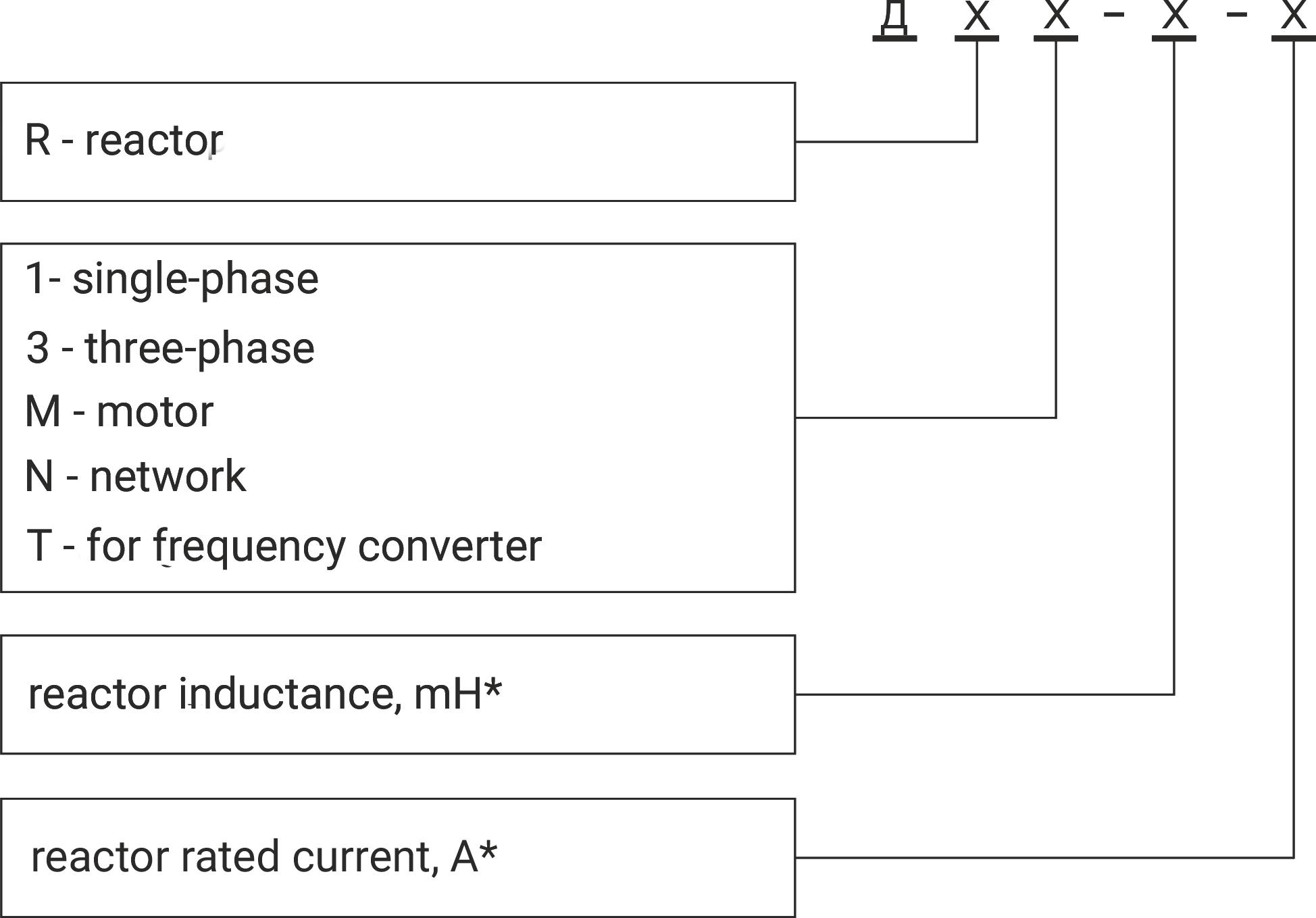

Transformer types designation.

Example of designation:

DR3-0,14-400 – Three-phase reactor, inductance is 0,14 mH, rated is current 400 А

| Parameter | Units | Default | Possible options |

| Coupling sizes | mm | At discretion of the manufacturer | Indicated in the questionnaire |

| Overall dimensions | mm | At discretion of the manufacturer | Indicated in the questionnaire |

The service life of reactors is 20 years. The warranty period is 24 months from the date of sale, unless otherwise agreed with the customer. Reactors are impregnated in the insulating compound assembly by dipping method, or by vacuum impregnation method according to design documentation. The reactor is considered fit for operation only after passing all the points of acceptance tests.