DRM - motor reactors

Motor reactors are used in circuits of converters of AC drives. Depending on the type of electric drive, the installation of motor reactors copes with the following tasks:

- ensuring continuity and smoothing of the motor current ripple;

- limiting the short circuit current in the load circuit of the converter;

- switching overvoltage suppression and compensation of supply line capacity

Construction of the magnetic system of reactors of DRM type – bar with clearance, with magnetic core, made based on UNICORE technology with butt joint, 1 non-magnetic clearance is located in the middle windings, electrotechnical steel NV30S -120, sheet thickness is 0.3 mm. Right-hand windings, material – aluminum. At customer's request, windings can be made of copper wire or bus.

DRM reactor parameters

|

Type of reactor |

Voltage class, kV |

Inductance, mH |

Rated current, A |

| DRM-3,8-16 | 0,7 | 1,83 | 16 |

| DRM-1,3-48 | 0,7 | 1,83 | 16 |

| DRM-1,5-36 | 0,7 | 1,47 | 20 |

| DRM-2-32 | 0,7 | 0,98 | 30 |

| DRM-0,1-60 | 0,7 | 0,73 | 40 |

| DRM-0,3-40 | 0,7 | 0,59 | 50 |

| DRM-0,4-150 | 0,7 | 0,48 | 60 |

| DRM-0,45-110 | 0,7 | 0,25 | 115 |

| DRM-0,05-110 | 0,7 | 0,2 | 150 |

| DRM-0,05-150 | 0,7 | 0,16 | 180 |

| DRM-0,07-150 | 0,7 | 0,18 | 180 |

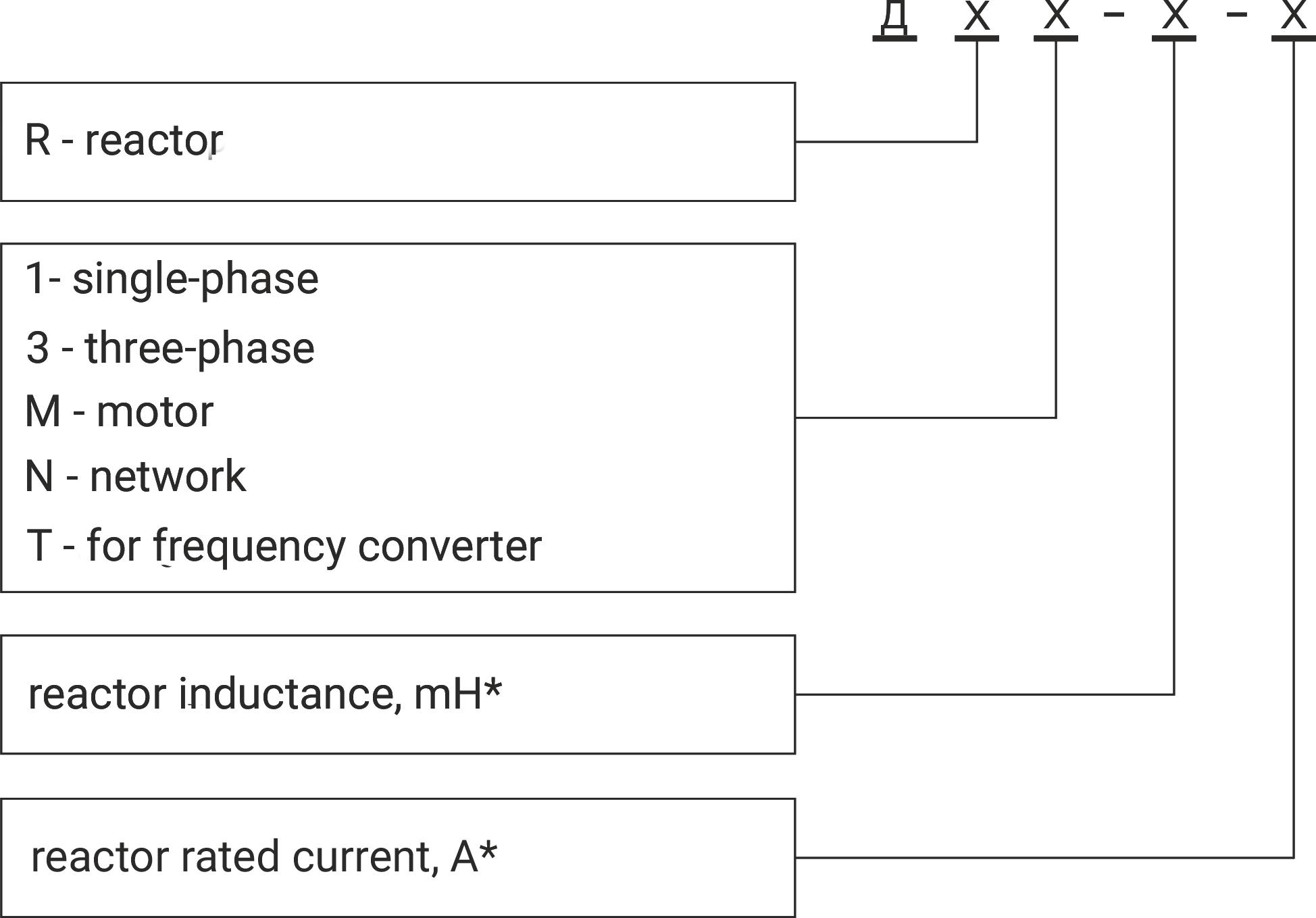

Designation Type

Example of designation:

DRM-3,8-16 – Motor reactor, inductance 3,8 mH, rated current 16 А

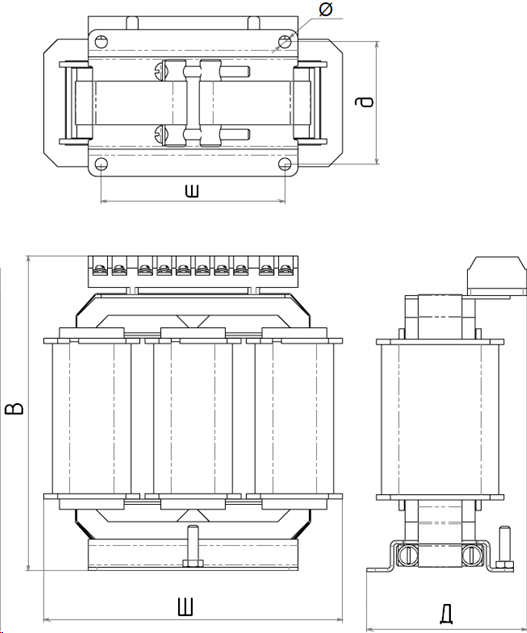

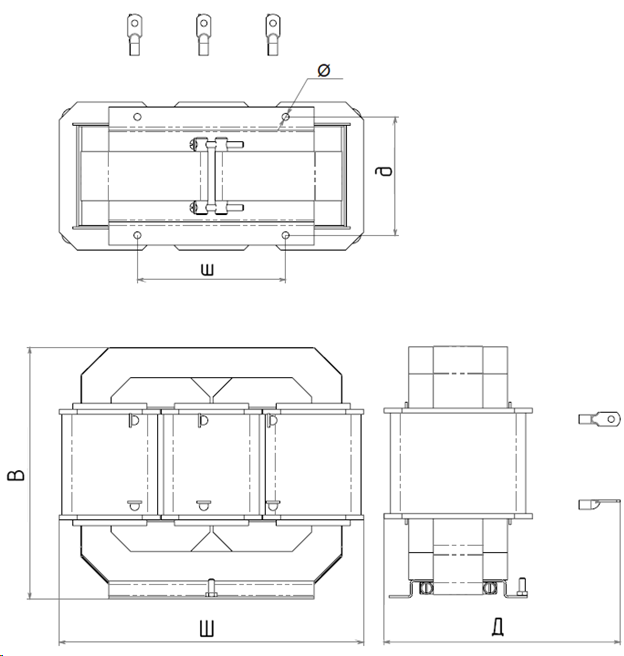

Overall and coupling dimensions DRM reactors

| Type of reactor | W | L | H | Weight | Picture |

| mm | mm | mm | kg | № | |

| DRM-3,8-16 | 205 | 200 | 200 | 13 | 1 |

| DRM-1,3-48 | 205 | 200 | 200 | 18 | 1 |

| DRM-1,5-36 | 205 | 200 | 200 | 17 | 1 |

| DRM-2-32 | 205 | 200 | 200 | 18 | 1 |

| DRM-0,1-60 | 205 | 200 | 200 | 12 | 1 |

| DRM-0,3-40 | 205 | 200 | 200 | 13 | 1 |

| DRM-0,4-150 | 280 | 250 | 210 | 25 | 2 |

| DRM-0,45-110 | 205 | 220 | 180 | 17 | 2 |

| DRM-0,05-110 | 205 | 220 | 180 | 18 | 2 |

| DRM-0,05-150 | 280 | 250 | 210 | 23 | 2 |

| DRM-0,07-150 | 280 | 250 | 210 | 25 | 2 |

* - изготовитель оставляет за собой право вносить изменения с целью улучшения качества продукции до согласования с заказчиком.

Picture №1

Picture №2

The service life of reactors is 20 years.

The warranty period is 24 months from the date of sale, unless otherwise agreed with the customer. Reactors are impregnated in the insulating compound assembly by dipping method, or by vacuum impregnation method according to design documentation. The reactor is considered fit for operation only after passing all the points of acceptance tests.